ISO 7379 SHOULDER SCREW GRADE 12.9

| Thread Size | #1-64 to 1 1/2 - 8 |

|---|---|

| Shoulder Diameter | 3mm To 36mm |

| Materials | Stainless steel, alloy steel, aluminum, titanium, brass, Monel |

| Finishes | Black oxide, plain, passivated finish |

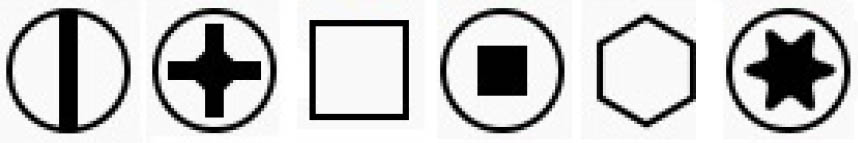

| Drive Type | Hex, slotted drives and six-lobe |

| Thread Size d | M5 | M6 | M8 | M10 | ||

|---|---|---|---|---|---|---|

| P | Pitch | 0.8 | 1 | 1.25 | 1.5 | |

| ds | Nominal Size | f9 tolerance | 6.5 | 8 | 10 | 13 |

| max | 6.487 | 7.987 | 9.987 | 12.984 | ||

| min | 6.451 | 7.951 | 9.951 | 12.941 | ||

| b | max | 9.75 | 11.25 | 13.25 | 16.4 | |

| min | 9.25 | 10.75 | 12.75 | 15.6 | ||

| dk | For plain heads | max | 10 | 13 | 16 | 18 |

| knurled heads | max | 10.22 | 13.27 | 16.27 | 18.27 | |

| min | 9.78 | 12.73 | 15.73 | 17.73 | ||

| k | max | 4.5 | 5.5 | 7 | 9 | |

| min | 4.32 | 5.32 | 6.78 | 8.78 | ||

| s | Nominal Size | 3 | 4 | 5 | 6 | |

| max | 3.08 | 4.095 | 5.095 | 6.095 | ||

| min | 3.02 | 4.02 | 5.02 | 6.02 | ||

| t | min | 2.4 | 3.3 | 4.2 | 4.9 | |

| g1 | max | 2.5 | 2.5 | 2.5 | 2.5 | |

| g2 | max | 2 | 2.5 | 3.1 | 3.7 | |

| ds1 | max | 3.86 | 4.58 | 6.25 | 7.91 | |

| min | 3.68 | 4.4 | 6.03 | 7.69 | ||

| e | min | 3.44 | 4.58 | 5.72 | 6.86 | |

| r | min | 0.25 | 0.4 | 0.6 | 0.6 | |

| Thread Size d | M12 | M16 | M20 | ||

|---|---|---|---|---|---|

| P | Pitch | 1.75 | 2 | 2.5 | |

| ds | Nominal Size | f9 tolerance | 16 | 20 | 25 |

| max | 15.984 | 19.98 | 24.98 | ||

| min | 15.941 | 19.928 | 24.928 | ||

| b | max | 18.4 | 22.4 | 27.4 | |

| min | 17.6 | 21.6 | 26.6 | ||

| dk | For plain heads | max | 24 | 30 | 36 |

| knurled heads | max | 24.33 | 30.33 | 36.39 | |

| min | 23.67 | 29.67 | 35.61 | ||

| k | max | 11 | 14 | 16 | |

| min | 10.73 | 13.73 | 15.73 | ||

| s | Nominal Size | 8 | 10 | 12 | |

| max | 8.115 | 10.115 | 12.142 | ||

| min | 8.025 | 10.025 | 12.032 | ||

| t | min | 6.6 | 8.8 | 10 | |

| g1 | max | 2.5 | 2.5 | 3 | |

| g2 | max | 4.4 | 5 | 6.3 | |

| ds1 | max | 9.57 | 13.33 | 16.57 | |

| min | 9.35 | 12.96 | 16.3 | ||

| e | min | 9.15 | 11.43 | 13.72 | |

| r | min | 0.6 | 0.8 | 0.8 | |

*adjusting shank tolerance:

․ steel h8 or f9

․ stainless steel f9

**on stock Ø12, standard value Ø13

***not standardized dimensions

Check Checklist for Choosing Right Hex Head Shoulder Screw

A well established shoulder bolt manufacturer in India, our extensive inventory can assure you that we have the custom shoulder screws in all standard sizes. Rimco Overseas is shoulder bolt supplier in bulk at wholesale prices.

- Material Compatibility

- Environmental Conditions

- Load Requirements

What are shoulder screws used for?

Much like all other screws, shoulder screws are meant to hold objects together and in a particular position. However, these screws are designed for use in parts which requires a mounting pin, joint, shaft, dowel, pivot, or sliding motion.

Items such as:

- Bearings

- Bushings

- Machinery support

- Motion guiding

- Precision spacing

These types of screws are commonly used in mechanical applications such as:

- Engines

- Linkages

- Pulleys

- Vacuum systems

How do I select the right shoulder screw for my application?

To choose the correct shoulder screw for your application you will need to know the specifications needed for the head, shoulder, threads, and the material the screws will need to be made from. Shoulder screws are generally specified by their shoulder diameter and then by the shoulder length. The overall length of the shoulder screw includes the head height as well.

Screw Head

The screw head drive can be slotted, Phillips, square, Robertson, hex, or a variety of specialty hex shapes. The diameter of the head is typically twice the head height, and 30-50% larger than the shoulder diameter, with a flat top. They also generally have an undercut between the shoulder and the bottom of the head to allow components to mount flush against the head when installed.

Screw Threads

The threads of the shoulder screw must not exceed the shoulder diameter. The threads are typically relatively short but can be manufactured to any required length. The thread neck, which is the space between the shoulder and the threads, is typically undercut to allow it to seat flush with the threaded component. This is also the weakest point in the screw and over-torqueing can cause the screw to break or fracture at this point.

Screw Materials

Shoulder screws can be made from a variety of materials but they are almost always made out of a type of steel. The most common materials include:

- 303 Stainless Steel

- 316 Stainless Steel

- 17-4 PH Stainless Steel

- 416 Stainless Steel

- Alloy Steel

- Mild Steel

- Brass

- Plastic

What Makes These Different From Regular Bolts?

Most people ignore bolts until one breaks and ruins their day. Shoulder bolts (some folks call them shoulder screws or stepped bolts) have that distinctive smooth section between the head and threads. This isn’t random – that smooth part lets attached parts rotate or slide without much friction. The precise sizing keeps everything properly spaced, which matters a ton in machines where tiny tolerances make or break performance.

Specifications:-

| Feature | Options |

| Standards:- | ISO 7379, ANSI B18.3, and (1016 & 1065 as per UPS Norms – Dia 4,5). |

| Materials:- | SS-304, SS-316, Heat-Treated Alloy Steel |

| Shoulder Sizes:- | 3mm up to 30mm (custom sizes if needed) |

| Thread Options | M3 to M24 (Metric); #10-32 to 3/4-10 (Imperial) |

| Shoulder Length Customized Solutions | 4mm to 100mm Customer-Specific Sizes Available on Demand |

| Head Type | Hex Socket Head |

| Finish Options | Plain, Passivated, Black Oxide |

Shoulder Bolts – Product Benefits

- High Precision & Dimensional Accuracy

Engineered per ISO 7379 and ANSI B18.3 standards, ensuring consistent shoulder dimensions for precise alignment and smooth rotation. - Corrosion Resistance

Manufactured using corrosion-resistant materials like SS-304 and SS-316, making them ideal for challenging environments. - Versatility in Applications

Perfect for integration into tooling, dies, jigs, pulleys, and heavy mechanical assemblies thanks to a robust, load-bearing design. - Smooth Bearing Surface

Features a polished shoulder that minimizes friction and wear, promoting efficient movement in sliding or rotating parts. - Available in Multiple Material Grades

Offered in various grades—SS-304 for general use, SS-316 for harsh environments, and Alloy Hardened for heavy-duty needs—providing the right solution for every application.

These high-performance Shoulder Head Bolts are widely used across segments such as Aerospace, Automotive, and Industrial applications.

Why Our Shoulder Bolts?

High Precision That Actually Matters

Built to meet ISO 7379 and ANSI B18.3 standards, so they maintain consistent dimensions. The tight tolerances (h9 grade) really matter because tiny variations can cause huge headaches later. We’ve seen whole production runs scrapped because of loose tolerance fasteners – not something you want to deal with. Each batch gets thoroughly checked – nothing leaves that doesn’t measure up perfectly.

Corrosion Resistance

Made from like SS-304 and SS-316, these hold up in tough environments where ordinary fasteners rust away to nothing. The passivated finish on the stainless versions gives extra protection against chemicals and moisture. Might seem excessive for some jobs, but for equipment sitting outside or in harsh industrial settings? That protection pays for itself many times over.

Works In Pretty Much Everything

Great for tooling, dies, jigs, pulleys, and heavy mechanical assemblies because of their solid, load-bearing design. The ground shoulders create bearing surfaces that normal bolts just can’t match. Put these in automation systems, conveyor equipment, or precision machinery, and you’ll notice the difference right away – smoother operation and way longer component life.

Super Smooth Where It Counts

Has a polished shoulder that cuts down on friction and wear, letting parts slide or rotate efficiently. This fine surface finish (around Ra 0.8) often means you don’t need separate bushings – so assembly gets simpler while keeping exact tolerances. Bottom line? Less maintenance, longer service life, and fewer surprise problems ruining your day.

Different Materials For Different Jobs

Not every job needs the same stuff. SS-304 works fine for most general uses. Need something tougher for caustic environments? SS-316 handles that perfectly. And for those really demanding load-bearing spots, the heat-treated alloy steel versions give superior strength where regular fasteners would just bend and give up.

Real-World Uses of our Shoulder Bolts

These specialized bolts solve actual problems across many industries:

- Automotive segments use them for assembly fixtures, stamping dies and test equipment where precise movement really matters.

- Aerospace facilities need them in ground support equipment and assembly tooling that absolutely cannot have any play or misalignment.

- Factory automation depends on them in robot systems, conveyor setups, and positioning equipment.

- Mold makers rely on them for ejector mechanisms and slide systems in injection molding operations.

- Medical equipment manufacturers choose them for pivoting components and adjustment mechanisms where smooth operation and cleanliness count.

Quality You Can Count On

Every batch goes through multiple quality checks – dimensional verification, material testing, performance validation. This strict attention to detail means fewer failures and more reliable performance in the field.

Custom shoulder bolts made to exact specifications are available when standard sizes just won’t work. Just provide your specs for quick quotes and production.

shoulder bolt dimensions

ANSI B 1.13 M, ISO 262

Material: ASTM A574M alloy steel

Hardness: Rc 36-43

Shear Stress: 660 MPa

Tensile Stress: 1100 MPa based on minimum thread neck area (G min.)

All dimensions in millimeters. *Shoulder diameter tolerance h8 (ISO R 286)

Shoulder Bolt Application

- Nuclear Energy Sector

- Oil & Gas Industries

- Petroleum Industries

- Defence Industry

- Chemical Industry

- Aerospace Industry

Stainless Steel Shoulder Bolt Testing Tool & Equipment

- Micrometer

- Smooth plug gauge

- Thread gauge

- Coordinate Measuring Machine

- Roughness tester

- Image measuring instrument

- Routine inspection of calipers